HYDROCHUTE SYSTEMS

Why Choose Hydro Chute?

Hydro Chute was built on the back of a long-established cleaning & maintenance business, Hydro Wash Ltd, which began trading in 2003.

Refuse chute steam cleaning and disinfection continue to be a core part of what we do, keeping chutes free from combustion load (solidified fats, oils and proteins that cling to the inside of the chute) and the odours that accompany such.

As a result of this direct involvement with chutes in high and low-rise residential buildings, hospitals and hotels across the UK, we were approached by several landlords and managing agents who were struggling to find a reliable solution for inspection, testing, repairing, servicing, manufacture, installation and certification (fire compliance).

Hence, we started the journey of proving contractor competence, which, of course, is still underway. The foundation that underpins our competency is, firstly, that all our engineers are in-house employees, all of whom have benefitted from industry-leading specific technical training by BRE, specifically focussing on refuse chute inspection, testing, servicing and installation. This training is unique to us. We also run an in-house training scheme for all new starters so they, too, can benefit from this best-in-class technical education.

Our team also possesses robust fire-stopping credentials along with fully qualified fire risk assessors. All are in-house employees.

We are ISO 9001 and ISO 14001 compliant. You can be assured that we have reliable and robust processes and standards that are independently audited.

Finally, please do ask us about our industry-leading recycling solutions.

Hydro Chute was born

After observing the common issues and frustrations shared with us, we set out not only to become a manufacturer of chute equipment but to improve on the historic design and quality, particularly in the areas of fire compliance, user experience and life expectancy.

This approach has led us to become market leaders in our industry.

All equipment is made in Yorkshire and will last for decades, not just for a few years.

All equipment is “made-to-measure” for a perfect fit.

Any size – any colour – any chute- our equipment will fit perfectly, thanks to our on-site surveying and manufacturing expertise.

Significant design & installation expertise.

All equipment is designed to hold back fire and smoke for 240 minutes.

Compliant with:

BS 476 Part 20 / 22:1987, BS 1703:2005, BS 476-31.1, BS EN13051-2:2007 + A1:2009.

Chute Hoppers

Our Range

We are the UK’s fastest-growing chute company, meeting and exceeding not only quality and manufacturing expectations, but also fire performance and smoke-tightness requirements.

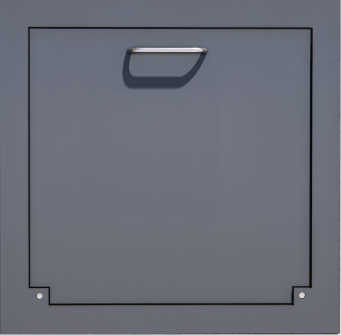

Self-Closing Standard Chute Hopper

Self-Closing Standard Chute Hopper

The superior design, materials, and in-house manufacturing, installed and tested by our own engineers, ensure that this hopper becomes an economical choice even though it is likely to be a little more expensive than others to buy. That small extra investment will deliver a super strong product capable of withstanding constant daily use, misuse and abuse for decades.

Self-Closing & Interlocking Chute Hopper

Self-Closing & Interlocking Chute Hopper

The same quality and durability as our standard door but with electromagnetic interlocks or drop-bolts. Compatible with all other manufacturers’ installations.

Self-Closing, Interlocking Multi-Waste-Stream Hopper

Self-Closing, Interlocking Multi-Waste-Stream Hopper

All of the above features are standard but with the inbuilt functionality to allow residents to select one of up to 3 waste streams, thus allowing them to recycle their waste appropriately. Of particular note is the fact that the electric button housing has also passed the same rigorous fire testing as the hopper itself, achieving the same 240-minute rating. This is also true of any of our other hoppers / doors requiring electrical component housing. Compatible with all other manufacturers’ installations.

Self-Closing Side-Hinged Locking Chute Door

Self-Closing Side-Hinged Locking Chute Door

Typically used in hospitals and hotels for linen, these are designed and built to match the exacting specification of our standard refuse chute hopper but with the addition of a lock, handle and key. We believe this is the most robust linen chute door available anywhere and will provide decades of service, even in the most demanding settings. Compatible with all other manufacturers’ installations.

Padlocked Chute Access Door

Padlocked Chute Access Door

Only for use by trained members of staff. These doors can also be installed retrospectively and are positioned conveniently to provide access for easy and stress-free chute unblocking. As you would expect, our side-hinged access door is designed and built to the same rigorous standards as everything else. Compatible with all other manufacturers’ installations.

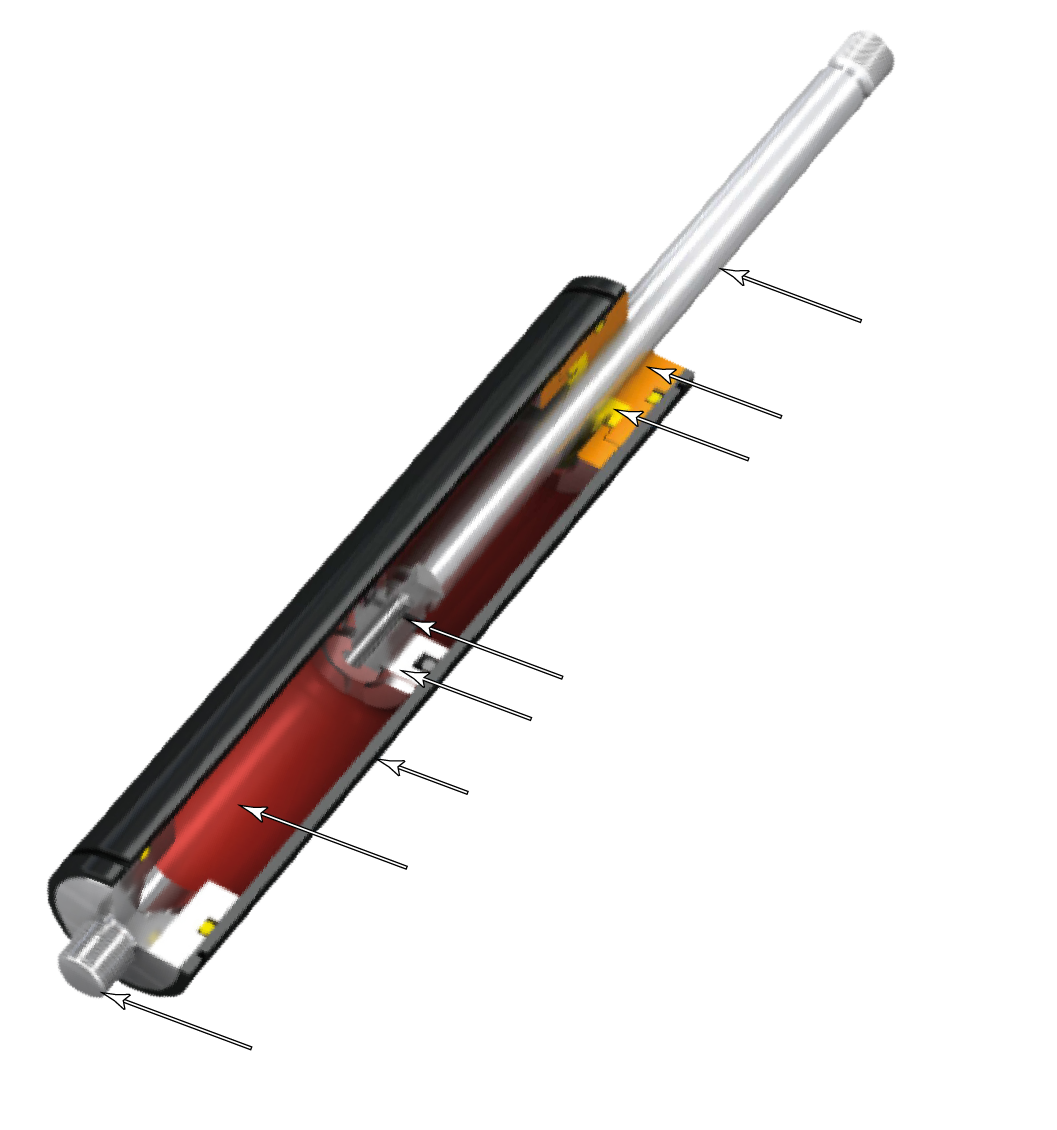

Soft-Close Pistons

Soft-Close Pistons

Our slim-design soft-close pistons feature a coated body and wear-resistant rods, ensuring exceptional durability and long service life. These maintenance-free systems deliver a consistent, controlled closing motion, providing smooth closure while enhancing user safety and quiet operation. Please note, if you specify these, the piston and housing will slightly reduce hopper dimensions.

CHUTE SYSTEM COMPONENTS

Our Range

We are the UK’s fastest-growing chute company, meeting and exceeding not only quality and manufacturing expectations but also fire performance and smoke tightness requirements.

The Hydro Chute Waste Streamers’ patented separation technology means there is finally a solution you can count on.

Hydro Chute Waste Streamer

The game-changing, waste streaming solution!

This super robust equipment can be retrofitted to your existing recycling chute, replacing your original and often temperamental equipment for good.

The Hydro Chute waste Streamer is installed and maintained under contract hire for a monthly fixed cost.

We are so confident in the quality and performance of our patented solution that the monthly hire charge includes all repairs and maintenance, meaning there are no unscheduled, unplanned, expensive repairs to budget for.

Watch Our Video Explanation

NO Stress, NO Hassle, and NO unexpected repair bills!

A fixed-cost Solution with no nasty surprises.

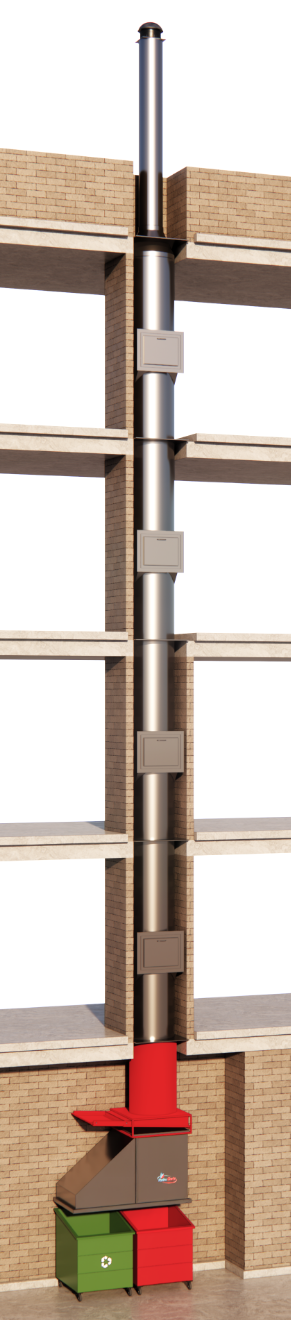

The galvanised steel chute throat is designed to house your choice of hopper / door and provide sufficient gradient to allow refuse to slide / drop into the chute.

The galvanised steel chute throat is designed to house your choice of hopper / door and provide sufficient gradient to allow refuse to slide / drop into the chute.

Chute Hopper Aperture / Throat

Chute Sections

Chute sections are installed and clamped together to create a fully seamless chute from the top to the bottom of the installation.

Auto Closing Fusible Link Activated Fire Closure Plate

SignificantdevelopmentbyHydroChutemeansthattheoperationandperformanceofourHydroChuteFCP’smakeustheclassleaderforchutesafetyinthebinroom.

Our standard FCP utilises tried and tested fusible link method of activation.

This has been proven over many decades to be an effective way to activate refuse / linen chute fire safety equipment located at the base of a chute.

The historical design of these units has remained the same for many decades. However, we at Hydro Chute saw the need for improvement in the way they operate, deploy and perform.

Uniquefeaturesinclude:

The elimination of springs! Our FCPs use gravity to close the plate. Gravity is completely reliable and does not wear out, snap or rust, unlike springs.

The plate is effortlessly reset- no spring tension to fight against!

All our FCPs are intumescent sealed and have been tested and proven to hold back fire AND SMOKE for 240 mins (4hrs)

The plate is manufactured to the standard required for it to also be used as a shutter for the safe swapping of bins. (6mm thick! as per BS1703 5.1.2)

It is, therefore dual purpose by design and constructed to tolerate and survive the impact of falling refuse from height.

AutoClosingSmoke/HeatActivatedFireClosurePlates

HydroChuteDischargePipe

This robust chute-extending pipe is fitted in the bin room directly to the concrete ceiling slab above, ensuring all waste from the chute above is directed and delivered safely into the bin. The anchoring method used to install the pipe to the slab ensures a fire and smoke-tight seal to the slab.

This leap forward from traditional designs negates the need for an auto-closing shutter at ceiling slab level in the bin room (often very difficult to reach / service / repair due to access and height issues) and then a second shutter at the bottom of the discharge pipe.

The bottom of the pipe is manufactured to accept our auto-closing Fire Closure Plate (FCP) and create a complete fire and smoke-tight seal between the pipe and the FCP unit.

Our Hydro Chute discharge pipe design has been tested (BRE) to hold back fire and smoke for 240 minutes, matching the standard of all our chute equipment.

This saves on installation costs and future maintenance / servicing costs, eliminating the need to hire mewps / scaffolding, etc., to negotiate the issues surrounding working at height that have been caused by traditional ceiling-mounted spring-loaded shutters.

DOWNLOADS

Testimonials

TrustedbyOurClients

Our Credentials

We are certified to internationally recognised ISO 14001 and ISO 9001 standards, demonstrating our commitment to environmental management and quality assurance.

Our Alcumus SafeContractor accreditation reflects our dedication to health and safety compliance across all our operations.

As members of the Institute of Fire Safety Managers, we uphold the highest standards in fire safety management.

Our Constructionline Gold Membership signifies our compliance with industry regulations and our commitment to excellence in construction and procurement.

CHAS accreditation verifies our compliance with health and safety standards, ensuring a safe working environment.

Our Acclaim Accreditation demonstrates our dedication to health and safety best practices, particularly within the construction industry.

Frequently asked questions

Is scheduled chute cleaning important?

As part of our core business, we provide servicing, fire and smoke testing, and a cleaning service that utilises hot water at high pressure with steam and detergent to remove any combustion loading with the chute. We feel like that’s good practice for any building manager to make sure that if there is a fire in the bin room or chute, there’s nothing in the chute that could provide a potential source of fuel for the fire.

How does Hydro Chute ensure contractor competency?

We put a lot of effort into the training of our employees; what we discovered

was that pre-Grenfell, there was no refuse or linen chute-specific training on the

care and maintenance of chutes. So, we approached the building research

establishment (BRE) to ask what we could do about that. Hydro Chute

collaborated with BRE, and we’ve produced a training course that allows all of

our engineers and operatives to achieve certification on refuse chute-specific

fire safety, servicing, installation and maintenance.

So that provides a golden thread that runs all the way from manufacturing into

servicing and then certification to provide great comfort for anyone who has

Hydro Chute installed in their building.

Why don’t you use springs to operate your auto-closing FCPs?

One of the most common designs on the marketplace at the minute uses

springs and tension to close. One of the issues with that is the strength and

sheer force required to reset the plate, and we’ve had instances of that being a

problem for many caretakers. Resetting a Hydro Chute fire plate is easy; it’s a

much safer reset and uses a lot less strength, effort, and force for the

caretakers. It also doubles as a manual closure plate, so it can be used to shut

the bin chute off so the caretaker can safely change the bins.

1

1